Integrity . . . Skill . . . Execution . . . Karma

... IN THE BEGINNING ...

On the plateaus of the Himalayas, close to the sky, the ancient Tibetan art of rug

making has been passed from one generation to the next. During the last 70

years, this craft tradition has passed from one culture to the next by virtue of

training and skilled hands of Tibetans exiled from their homeland in 1959, while

traveling thru Nepal, where the Tibetan carpet making tradition lives on.

The art of making Tibetan carpets by hand using the finest materials is honored and nurtured by

RugGuy Galleriez. Each carpet is carefully hand-knotted, the methods virtually unchanged from time

before written instruction, using traditional techniques in the

execution of contemporary design. The subtle imperfections of

natural materials and the variations of the human touch are celebrated

by RugGuy Galleriez in every stage of the process. The result of a

commitment to promote individual inspiration in all of its production.

Truly, each carpet is unique unto itself, and the Nepalese weavers

enjoy the challenge of making new designs and constructions,

allowing a little of their own spirit into the soul of each rug.

INTEGRITY OF THE WOOL

Tibetan highland sheep, semi-domestic and hardy, roam across the great Tibetan

plateau. The sheep run basically wild and because of the great height of 15,000 feet

at which they live, the wool we get from Tibet is a very strong and long staple fiber.

Unquestionably, Tibetan wool is among the finest natural fibers in the world for rug

making. It is silky yet resilient and strong, lustrous and rich with lanolin, the natural

secretion sheep give off to protect their skin which, in wool, gives it the natural

protection that 'Scotchguarding' simulates. Tibetan wool

contains myriad shades of brown and black as well as

countless variations of white. Previously brought by Yak

over the Himalayas, now by truck, unscoured and dripping with lanolin,

Tibetan wool is the untamed soul of each of these RugGuy Galleriez

carpets.

The wool is unloaded near a flowing stream from the mountain watershed

in the town of Pokhara. It is separated into light, medium and dark color groups, and vigorously

washed in the cool clear water, then lay out in the brilliant sun to dry. Soon to be loaded and carted

into the villages to be carded.

CARDING

The first step in the creation of RugGuy Galleriez’s rich yarns is called

carding. Like all of the steps used in creating their rugs, this one is

performed entirely by hand. One handful of wool is placed between two

metal-toothed paddles and gently combed until the fibers are roughly

aligned. It is a labor-intensive process that has been traditionally used to

prepare wool for spinning. While a machine could comb the wool and align

its fibers in the blink of an eye, it would break the fibers and make the

resulting yarn too uniform. By comparison, hand carding respects the

precious fibers, and the resulting yarn is very long and distinctively raw. Hand carding is a step most

manufacturers avoid because it requires massive organization and human effort as well as substantial

added expense, but RugGuy Galleriez believes that yarn quality is too important to compromise.

Starting with the best product at the beginning naturally produces superior results.

SPINNING

In homes and small village compounds RugGuy Galleriez’ workers sit at

simple, foot-powered wooden wheels carefully guiding the labor-intensive

process of spinning with a practiced hand, a steady foot and a keen eye.

The balance between wheel and hand is too delicate to yield a mechanically

uniform product. Happily, the rich, organic texture of the resulting yarn

couldn't be more beautifully imperfect for RugGuy Galleriez’ Rugs.

DYEING

Dyeing is one stage in the production process where RugGuy Galleriez

believes that the modern improves on the ancient. In keeping with the Tibetan

tradition the skeins of raw yarn are dyed in small lots by hand called ‘pot-

dyeing’. The pigments are provided by Swiss metal complex dyes. They

enable color consistency well within the acceptable range of a handmade

production. The variation of absorption in the hand spun yarn creates an effect

called ‘abrash’. Just as important, the Swiss dyes enable RugGuy Galleriez access to a far greater

range of colors than ancient rug makers ever had as they constantly evolve the palette and decorative

applications of RugGuy Galleriez Tibetan Carpets.

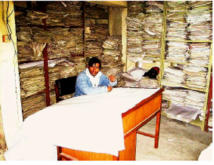

COLOR SELECTION & FIBERS

RugGuy Galleriez has a standardized color system called ‘color-podz’. Each

sample shows the cut (velvet) and looped execution of the wool, along with the

silk. Fibers may also be dye matched to paint chips, fabrics, or any other

inspiration. Dyemasters in Nepal have an arsenal

of dyestuffs to work from and consistently amaze

clients with their expertise.

When a match is made it is recorded in the

logbook to be used for formulating the quantity

needed for a rug. This includes a small amount of

yarn as well.

In addition to Himalayan wool, and Chinese or Indian silk, there are a variety of organic fibers

including hemp, sunpatt, nettle, jute, banana silk, and soy silk to name a few.

DESIGNING (GRAPHING) THE PATTERN

Once a design or rendering is approved, it is sent to the factory in

Kathmandu. There it is printed and studied by the artist in charge

of graphing it. A large full scale drawing is made which shows

each portion of the design, and consequently each knot location

that is to be tied. The graph is a work of art in it’s self. The

finished graph is carefully folded, wrapped in plastic, and sent to

the loom where it is hung above the weavers eyelevel for review

as the rug is being knotted. In addition a color key is supplied of

the dyed yarn, as the graph is typically painted with “wild colors’

so the weavers know where each color and texture are separated. This in particular when a tone-on-

tone design is being made.

WEAVING

RugGuy Galleriez Tibetan Carpets are woven by

hand, knot by knot. Each knot results in a single

point of color in the pile of the finished carpet. A

standard 9x12 foot RugGuy Galleriez carpet

comprises between 525,000 and 1.5 million of

these individually handtied knots. An interesting

footnote to this story of incredible craftsmanship

and patience is that the company's weavers

employ the Tibetan Loop Senneh knot. In this

technique, each knot is tied around two warp threads, then looped

around a metal rod ‘dunde’ placed horizontally across the loom. When

a given row of knots is completed, it is hammered down to the prior

row with a ‘thowa’ mallet. The row is cut with a small knife called

‘churi’. The rod freed, and the pile exposed. After locking the row

with a weft thread, it is secured with a metal ‘panja’comb. Weavers at

the loom knot row after row, creating a dense, luxurious fabric. The

weavers pull each knot tight with a different force, and must work at the same pace as the weaver next

to them. There are 3 weavers working on a 9- foot wide loom. There is no advantage to being the

fastest when weaving a fine rug.

SHEARING + FINISHING

Once the weaving is finished and the carpet is cut down from the

loom the pile is crudely leveled with large steel shears. About 18” in

length, these Tibetan scissors ['Jam-tse'] are themselves a tool that

requires some time to master. The details are trimmed with a smaller

version that are primitive yet razor sharp. Those who do the shearing

use an old Tibetan weaver's trick lining the part of the scissors where

they put their fingers with wool, so they don't get blisters. After the

pile is cut down on the carpet's surface, long pointed scissors are used

to lightly emboss between different colors in the carpet, enhancing the clarity and vitality of the

designs.

WASHING

After the weaving process is complete, each Rugguy Galleriez Carpet is finished with a

technologically advanced process that gently cleans, softens, and ages each rug, enhancing its patina

and highlighting its color. A resin finish is also applied, augmenting the wool’s natural resistance to

stain and setting the colors. Washing is a process where modern technology actually accentuates the

hand-made charm, and the lush feel of the carpet.

RugGuy Galleriez Carpets are finished with the Tibetan Wash system developed and performed by

experts in an effort to continue environmental awareness “BIO-WASH” strives to recycle precious

natural resources, and recover damaging post-wash residual waste.

RugGuy Galleriez helps promote the weavers’ welfare and their families

through the “CARE & FAIR” program.

RugGuy Galleriez is a proud partner with Goodweave. A portion of each sale is

donated directly to Goodweave, to help eradicate child labor.

RUGGUY GALLERIEZ, INC.

312.933.8321

Mark@TheRugGuy.com

www.TheRugGuy.com